Interested? Contact us to start a sample order, we will offer special discount!

Contact Us TodayQuality Control Can be Seen Throughout Production

Processing Inspection & Performance Testings

Commonly Asked Questions

There are mainly 4 reasons to the core drill bit vibration during coring:

- Excessive pressure on the drill,

- Inadequate water supply,

- Too high speed

- The worn drill bit

So, in order to avoid the vibration, you should reduce the speed, exert proper pressure on the drill, supply enough water, and check the drill bit before coring.

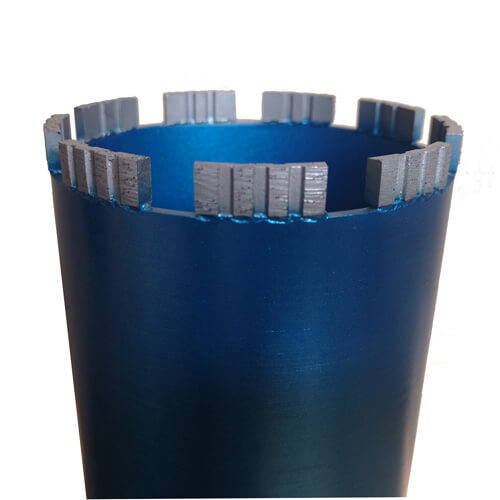

Dry diamond core drill bit and wet diamond core drill bit are unique in their ways. Some situations require the use of wet core drilling while other cases are more suited for dry core drilling. Therefore, it is essential to use not only the right core drill bits but also suitable accessories.

The brass ring, drill stand, and anchor bolts are ideal for use in the wet core drilling operations. The other accessories that are suitable for the dry core drilling can also be used for the wet core drilling. The pilot drill is more suited for use for dry core drilling.

Despite the hardness and abrasiveness of the materials, the diamond core drill bit life is also affected by the drilling speed, the pressure and the lubrication.

The hardness and abrasiveness of materials can vary significantly. Each individual's drill speed, pressure and amount of lubrication also varies significantly. As a result, it is nearly impossible to estimate the life of a diamond bit.

However, the following techniques will improve the diamond core drill bit life: proper drill speeds, low drill pressure and adequate use of water for lubrication.

A pilot bit is a small drill bit located in the center of the hollow core drill bit, that keeps the bit centered while starting a hole. So, the pilot bit is necessary if there is strict requirement on the hole position.

However, there is drawback of the pilot bits, the pilot bit always wears out faster before the main core drill bit, so the pilot bit will increase the drilling time, if the material is very hard, the drilling time will be even longer.

That depends, if use the dry core drill bits, water is not necessary, because there are always venting holes or slots on the drill barrel of dry core drill bits. Also, the dry core drill bits are normally used on slow RPM devices, like angle hammer or rotary hammer drill. So, there won’t be that much heat generated, instead, an effective vacuum cleaner is necessary.

If use the wet core drill bits, water supply is necessary, because wet drill bits are used on handheld drill or the drill rig, these devices have high RPM, meanwhile the wet drill bits are always used to drill on hard concrete, reinforced concrete, bricks or blocks, a lot of heat will be generated during the coring process, cold water can be a good coolant.

Diamond Core Drill bits are mainly used for drilling holes on concrete, reinforced concrete, bricks, pre-stressed concrete, blocks. Or drilling holes for air-conditioning, water pipe, etc.